At Buffington Homes, our favorite thing is building beautiful personalized homes for customers in popular and up-and-coming areas all around Northwest Arkansas. But did you know that our building process is adding value to these new homes, the industry, and your community? Our use of manufactured components allows us to construct homes with greater precision and less waste than traditional framing practices. Here’s more about how it works!

What are manufactured components? They’re simply parts of your home, such as roof and floor trusses and wall panels, that are constructed in advance and sent directly to the job site for installation. Thanks to our manufacturing partner, we can increase the speed of our builds based on the following:

An expert team of carpenters can identify potential issues before components reach the job site, reducing the risk of delays and costly errors.

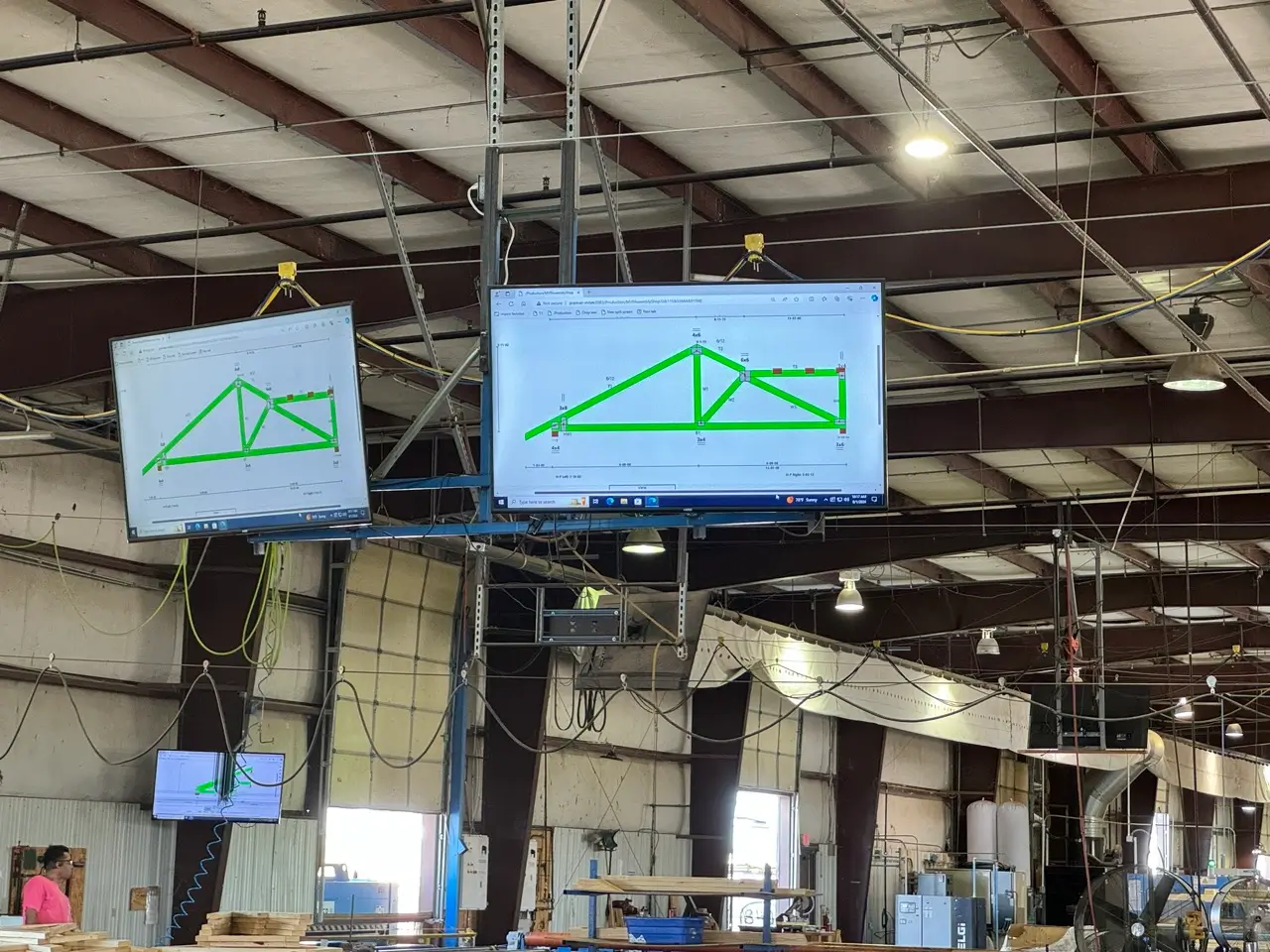

Components are developed using 3D design software so that precise cuts can be made using automated saws, optimizing structural integrity.

All components are clearly labeled and packaged, and they’re delivered on-time to the job site for efficient installation.

Predictability in component development, delivery, and installation makes project management easier and more accurate.

Not only that, but homes that are built faster are also less exposed to the elements, helping to preserve their integrity.

Our manufacturing partner has strong safety standards, consistent inspections, and regular safety training for workers. They also use cranes for assembly, which decreases the need for employees to work at heights; this can reduce the risk of injury, meaning fewer claims and lower insurance costs.

The use of manufactured components is greener than traditional house framing methods. With components, predictability and precision allow for 25% fewer wood products and 30x less job site waste than stick framing. This equates to a reduced need for forestry products (lessening the environmental impact) and fewer materials ending up in landfills once the job is completed. Additionally, precision cutting means that the structure itself has fewer gaps or discrepancies in its joints, allowing for more efficient heating and cooling.

Because our manufacturing partner uses 3D modeling software to plan each project for the most effective utilization of resources, our homes can be built faster, greener, and safer — and also more structurally sound. When joints fit together perfectly, the home itself is stronger and more likely to retain value in the years to come.

Are you ready to say yes to building a life you’ll love in a beautiful, personalized Buffington Home? Our building process is optimized so that you can get the best value and enjoy a home that fits your lifestyle! Discover more about our communities and floor plans and get in touch with us when you’re ready to get started!